Harness the power of machine data through cloud-based application

to streamline your manufacturing process.

Preferred by leading organizations in transforming their real-time manufacturing data into actionable insights

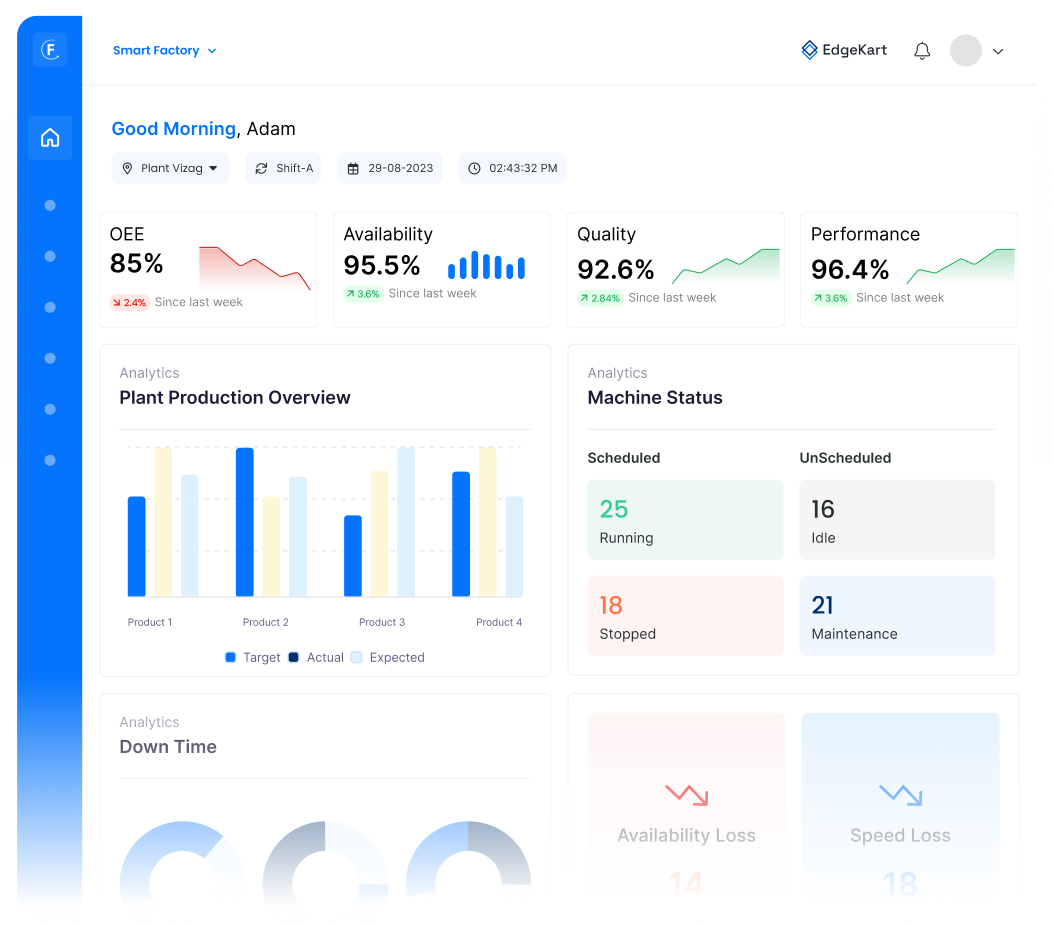

Unlock unparalleled efficiency with Facttwin's dual-edge in operational visibility and machine

health monitoring , catalyzing the shop floor’s performance and productivity.

Join the Facttwin Partnership Program to unlock new avenues for growth and innovation. Collaborate with us to extend your reach, integrate cutting-edge technology, and deliver exceptional value to your clients.

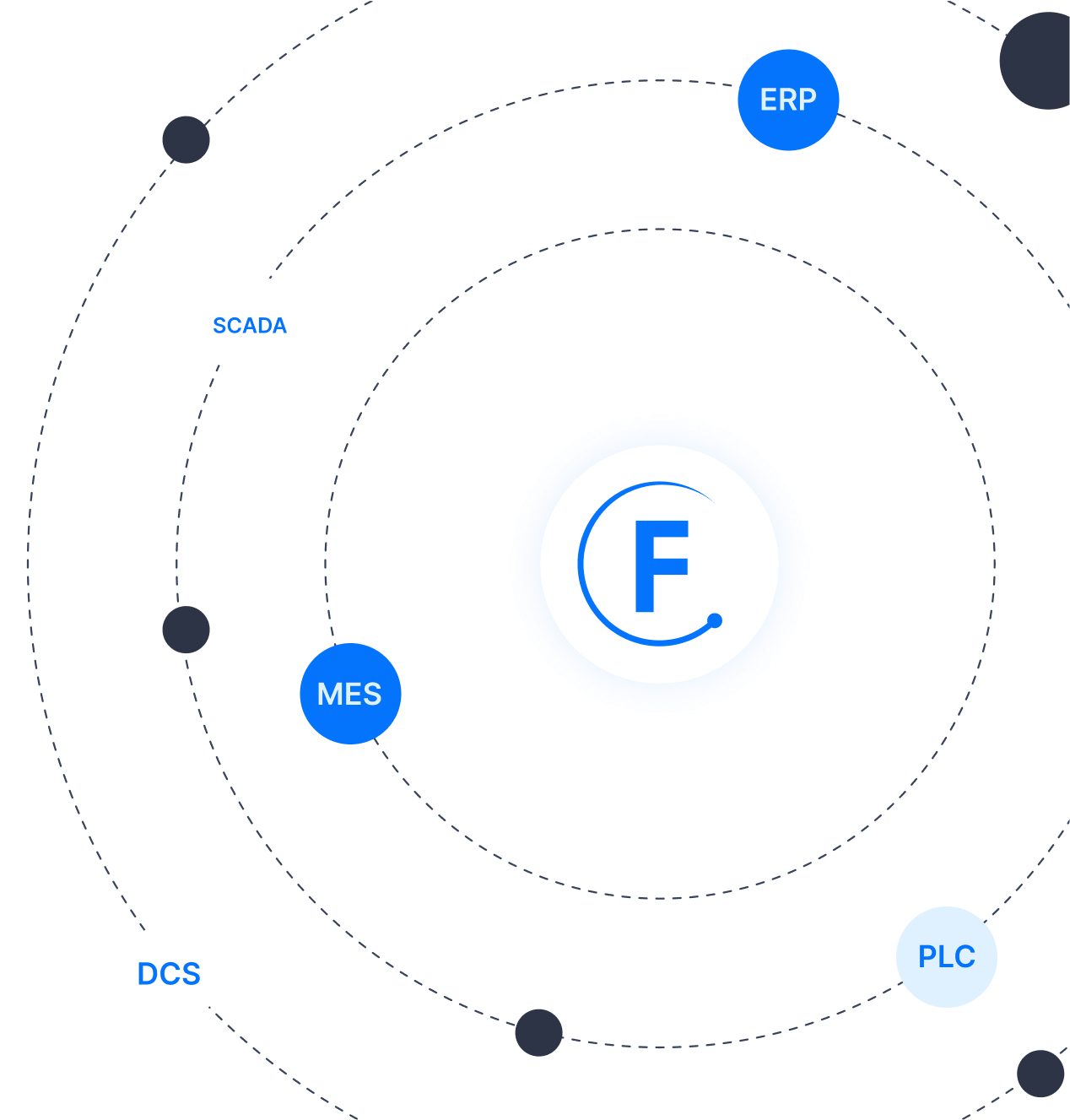

Effortlessly bridge your operations with Facttwin's robust integration suite. Connect legacy systems and modern applications like SCADA, MES, DCS, ERP & PLC; ensuring data fluidity and operational cohesiveness across your enterprise.

Discover real-world success stories and in-depth analyses showcasing how Facttwin has addressed challenges and delivered tangible results.